Weld Gases Suction System

- HOME

- MECHANICAL

- Welding - Exhaust Suction System

- Weld Gases Suction System

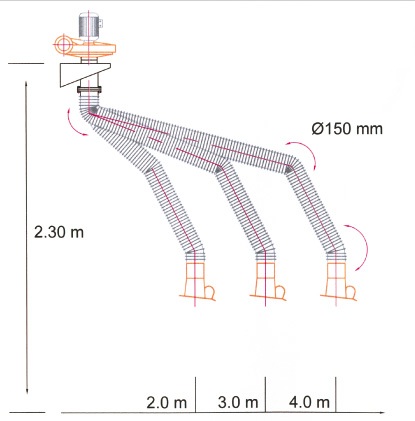

They are designed for constant weld points and weld cabin or training workshop. They can be mounted on the wall, column or console easily. This units are equipped with a cartridge filter. These systems work on the principle of superficial filtering. Top of the filter is covered by special materials so the dust is separated from filter. This filter is ideal to suck the weld fume. Cartridge filters are automatically cleaned with compressed air. Pressurized air is given homogenicly from the filter by using the rotating blower. The dust which is accumulated external surface is rejected to the outside and collected in the collection vessel. Cleanable filter cartridge, 5 m power cable with plug, engine protection switch and digital controller are all together; however, muffler and active carbon filter is optional.

Acrobat exhaust arms consist of air control damper hoods which carry itself and they are 360o rotatable. They can be adjust in any shape and they stay any position without help. The carrier carcass is inside a flexible hose which has the properties of 150 mm diameter, abrasion and high heat resistance.

- > Homepage

- > About Us

- > Our Services

- > Contact Us

- > EMA of Press

- > Insdustrial

- > Mechanical

- > Construction

- > Energy

- > Career

TR

TR EN

EN